THE PREMIUM CHOICE IN EPOXY COATINGS

THE PREMIUM CHOICE IN EPOXY COATINGS

#1 Rated Company in the Lehigh Valley

HIGH QUALITY CONCRETE COATINGS

Turn Your Old Garage Floor Into a Beautiful and Functional Masterpiece!

REQUEST A QUOTE

BRING BEAUTY, DURABILITY, AND LIFE TO YOUR CONCRETE. THE GOLDEN STANDARD OF CONCRETE COATINGS.

PREMIUM EPOXY COATINGS

Dirty, damaged, concrete floors put your home at risk and cause you to waste square footage.

Dirty, damaged, concrete floors put your home at risk and cause you to waste precious square footage and even money towards expensive repairs in the future.

The good news is, you can prevent all of the above and start enjoying the less-popular parts of your home. Find out why Golden Concrete Resurfacing is rated #1 for concrete floor coatings in Pennsylvania.

Dirty, damaged, concrete floors put your home at risk and cause you to waste square footage.

Dirty, damaged, concrete floors put your home at risk and cause you to waste precious square footage and even money towards expensive repairs in the future.

The good news is, you can prevent all of the above and start enjoying the less-popular parts of your home. Find out why Golden Concrete Resurfacing is rated #1 for concrete floor coatings in Pennsylvania.

0% Financing Available

Fast and easy

No hidden fees

No credit impact to check

Don't Sacrifice The Quality Of Your Install - Prequalify With Wisetack Today!

All financing is subject to credit approval. Your terms may vary. Payment options through Wisetack are provided by our lending partners. For example, a $1,200 purchase could cost $104.89 a month for 12 months, based on an 8.9% APR, or $400 a month for 3 months, based on a 0% APR. Offers range from 0-35.9% APR based on creditworthiness. No other financing charges or participation fees. See additional terms at http://wisetack.com/faqs.

0% Financing Available

Fast and easy

No hidden fees

No credit impact to check

Don't Sacrifice The Quality Of Your Install - Prequalify With Wisetack Today!

All financing is subject to credit approval. Your terms may vary. Payment options through Wisetack are provided by our lending partners. For example, a $1,200 purchase could cost $104.89 a month for 12 months, based on an 8.9% APR, or $400 a month for 3 months, based on a 0% APR. Offers range from 0-35.9% APR based on creditworthiness. No other financing charges or participation fees. See additional terms at http://wisetack.com/faqs.

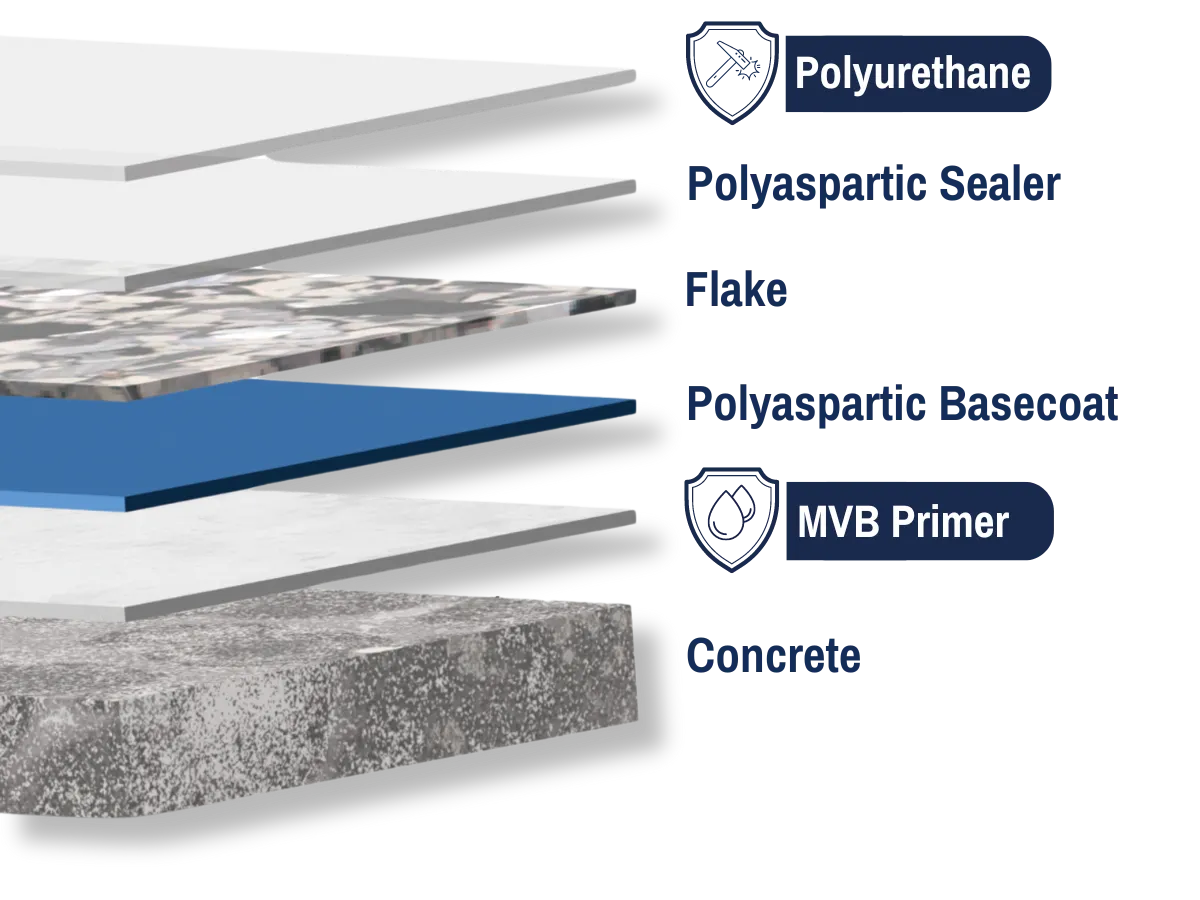

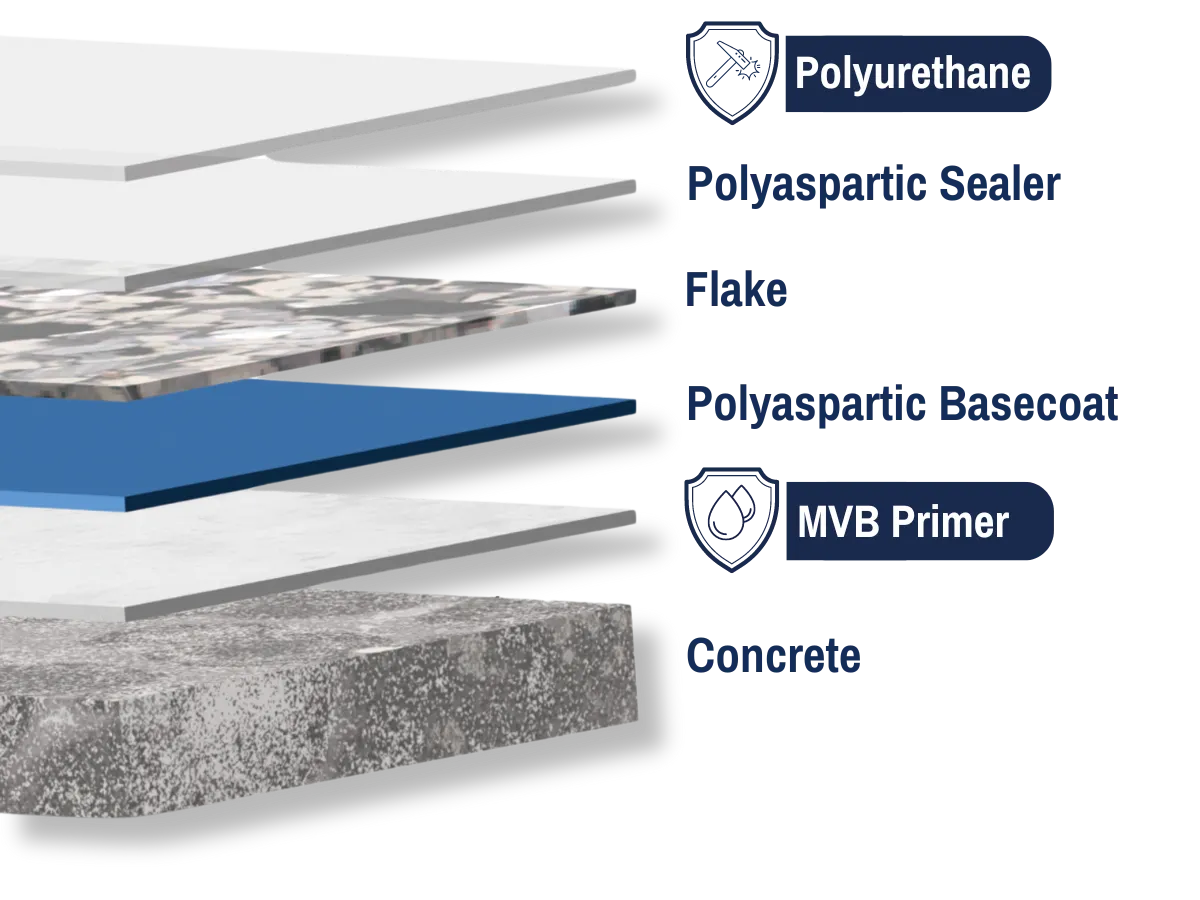

A SUPERIOR EPOXY COATING

Our Four Coat System

Our Superior Four Coat System

At Golden Concrete Resurfacing, we take pride in our meticulous and superior Four Coat system, setting us apart from the norm. While others may settle for only offering a two-coat approach, we believe in investing in quality for lasting results .

What Makes Our System Special?

Moisture Vapor Barrier Primer: Ensures a strong foundation

Pigmented Polyaspartic Basecoat:

Adds durability to withstand the test of time.

Stunning Flakes: Enhances the visual appeal and texture of your surfaces.

UV Resistant Polyaspartic Sealer: A sleek UV Stable finish for long-lasting protection.

Polyurethane Topcoat: Additional abrasion and chemical resistance.

Up to 40 Mill Thickness: More than 6 times thicker than most store bought kits.

A SUPERIOR EPOXY COATING

Our Four Coat System

Our Superior Four Coat Epoxy System

At Golden Concrete Resurfacing, we take pride in our meticulous and superior Four Coat system, setting us apart from the norm. While others may settle for only offering a two-coat approach, we believe in investing in quality for lasting results .

What Makes Our System Special?

Moisture Vapor Barrier Primer: Ensures a strong foundation

Pigmented Polyaspartic Basecoat:

Adds durability to withstand the test of time.

Stunning Flakes: Enhances the visual appeal and texture of your surfaces.

UV Resistant Polyaspartic Sealer: A sleek UV Stable finish for long-lasting protection.

Polyurethane Topcoat: Additional abrasion and chemical resistance.

Up to 40 Mill Thickness: More than 6 times thicker than most store bought kits.

Penetrating Epoxy Primer: Ensures a strong foundation

100% Solids Epoxy Intermediate Coat: Adds durability to withstand the test of time.

Stunning Flakes: Enhances the visual appeal and texture of your surfaces.

Single Component UV Resistant Polyaspartic: A sleek UV Resistant finish for long-lasting protection.

30 Mill Thickness: Two the thickness of polyurea systems and 6 times thicker than store bought kits.

WHO YOU'LL BE WORKING WITH:

What sets us apart?

At Golden Concrete Resurfacing, our dedicated team of trained technicians goes beyond expertise in epoxy coatings. We prioritize your experience, ensuring that you're not just a client but a valued partner in the process. Our technicians are not only skilled but also committed to accommodating your needs and providing clear, step-by-step guidance. So, sit back, relax, and trust us to transform your surfaces with precision and care.

WHO YOU'LL BE WORKING WITH:

What sets us apart?

OUR DEDICTATED TEAM

At Golden Concrete Resurfacing, our dedicated team of trained technicians goes beyond expertise in epoxy coatings. We prioritize your experience, ensuring that you're not just a client but a valued partner in the process. Our technicians are not only skilled but also committed to accommodating your needs and providing clear, step-by-step guidance. So, sit back, relax, and trust us to transform your surfaces with precision and care.

OUR REPUTATION:

Did You Know?

We are proud to be a part of the community and give back as much as possible. With every job completed, we donate to The Sanctuary at Haafsville to help dogs in need find a home. Keep scrolling to see what we offer and get a free estimate 👇

OUR REPUTATION:

Did You Know?

We are proud to be a part of the community and give back as much as possible. With every job completed, we donate to The Sanctuary at Haafsville to help dogs in need find a home. Keep scrolling to see what we offer and get a free estimate 👇

Proud to Sponsor

Our work speaks for itself...

Like what you see?

Use our visualization tool to see how it would look on your own concrete!

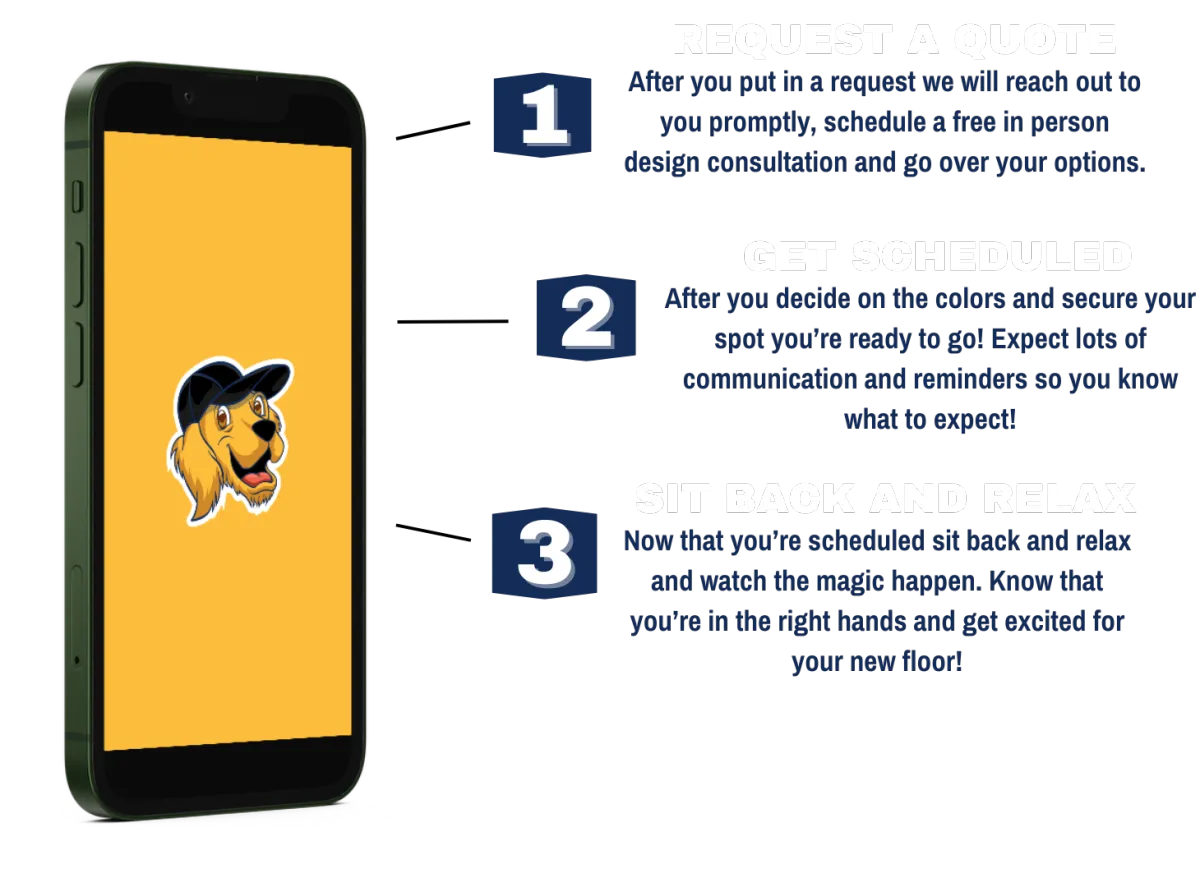

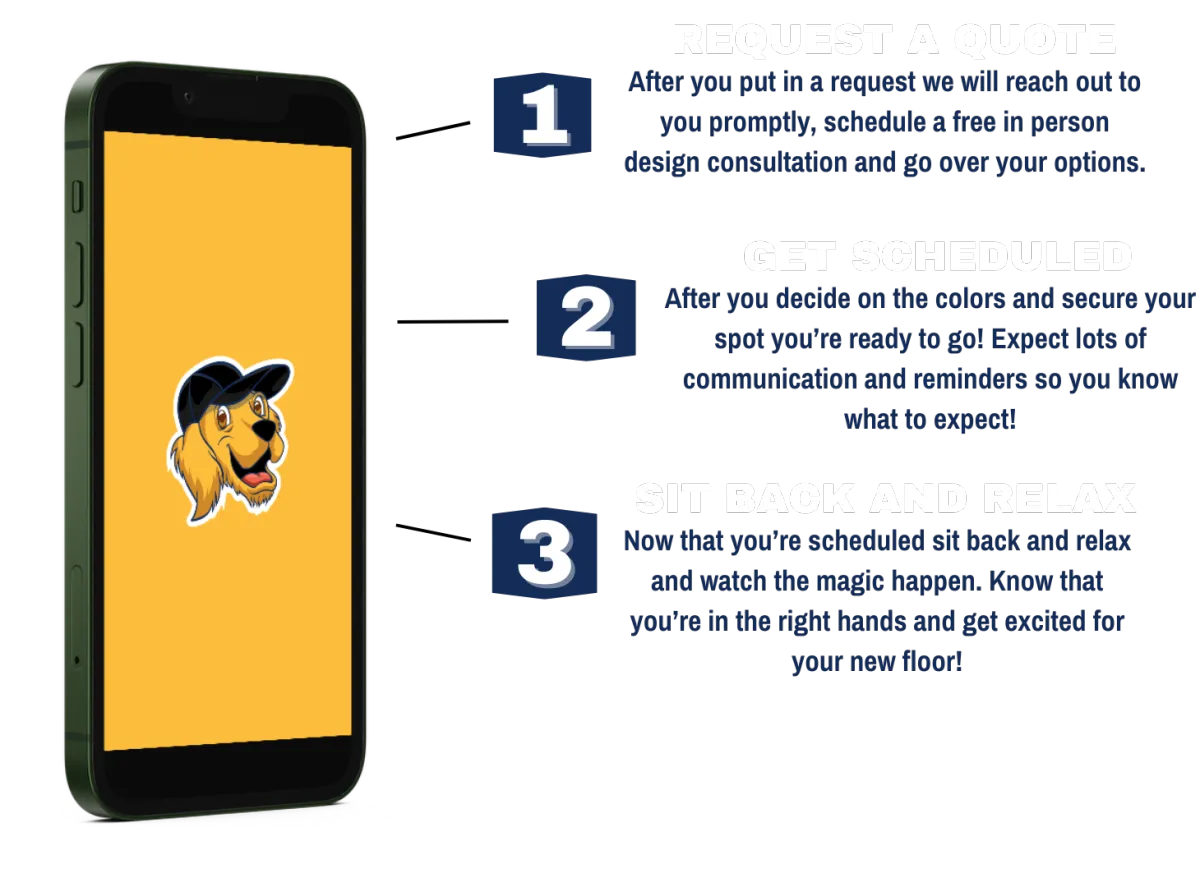

THE GOLDEN STANDARD OF CONCRETE COATINGS

Your time is valued thats why the process is easy a 1-2-3

Our work speaks for itself...

Like what you see?

Use our visualization tool to see how it would look on your own concrete!

THE GOLDEN STANDARD OF CONCRETE COATINGS

Your time is valued thats why the process is easy a 1-2-3

Frequently Asked Questions

How long does a coating last?

Our coatings are designed for long-lasting durability. You can expect our system to last up to as long at the concrete underneath of it, as long as it is properly maintained and the substrate is non-defective.

What's your warranty?

We stand by the quality of our work and provide up to a lifetime warranty. Our warranty covers against defects and ensures your satisfaction. You can find the entire warranty here.

How much does it cost?

The cost of an installation varies based on factors like the size of the area, system and number of coats chosen, condition of the concrete, and the complexity of the project. Although we provide personalized quotes to ensure a fair and accurate estimate, in general you can expect anywhere from $7-$16/sqft.

Why pay more for a "premium" coating?

In short, you'd pay more upfront for a premium coating because of what it will save you in costs and headaches in the future. Our 4 coat system is thicker and will stand the test of time due to both the bond with the concrete, and strength of the topcoat. The durable polyurethane topcoat protects the surface from wear and tear, while the epoxy moisture vapor barrier seeps into the concrete to ensure your floor won't bubble or peal, even decades after the install. Not to mention that the extra investment allows our skilled team to take the time to prep and coat your floor correctly and entirely. Overall, the price tag that may be a bit more than other quotes you received, however the difference is in the higher quality material we use, the trained technicians that know the importance of preparation, and a longer lasting floor that you won't have to redo in your lifetime.

How do you prep the concrete?

Prior to installing an epoxy coating we thoroughly prepare the concrete. This involves diamond grinding, repairing cracks or imperfections, and filling joints as needed. Diamond grinding is necessary to a strong bond to the surface of the concrete. Grinding removes dirt, stains, and existing coatings while creating a scratch pattern for the epoxy to "bite" into.

How long is the process?

The timeline depends on the size and complexity of the project. On average, most 2 car garages can be completed in a single day with our standard system. An additional topcoat or primer can add an extra day each.

How long do I need to stay off the floor for?

Typically, you can walk on the surface 24 hours after the final coat is applied. Full cure times may vary based on weather conditions, but are generally achieved within 72 hours which is when it is safe to return to normal use.

How much flake is put down?

We offer full flake floors which use about 50lbs of flake per every 500sqft. This provides consistency that allows us to achieve a desirable texture and aesthetic without sacrificing durability.

Will the coating yellow over time?

No! Our full flake coatings topped polyaspartic will not yellow over time. Our polyaspartic top coat is UV resistant, unlike some epoxy and polyurea top coats used.

Frequently Asked Questions

How long does a coating last?

Our coatings are designed for long-lasting durability. You can expect our system to last up to as long at the concrete underneath of it, as long as it is properly maintained and the substrate is non-defective.

What's your warranty?

We stand by the quality of our work and provide up to a lifetime warranty. Our warranty covers against defects and ensures your satisfaction. You can find the entire warranty here.

How much does it cost?

The cost of an installation varies based on factors like the size of the area, system and number of coats chosen, condition of the concrete, and the complexity of the project. Although we provide personalized quotes to ensure a fair and accurate estimate, in general you can expect anywhere from $7-$16/sqft.

Why pay more for a "premium" coating?

In short, you'd pay more upfront for a premium coating because of what it will save you in costs and headaches in the future. Our 4 coat system is thicker and will stand the test of time due to both the bond with the concrete, and strength of the topcoat. The durable polyurethane topcoat protects the surface from wear and tear, while the epoxy moisture vapor barrier seeps into the concrete to ensure your floor won't bubble or peal, even decades after the install. Not to mention that the extra investment allows our skilled team to take the time to prep and coat your floor correctly and entirely. Overall, the price tag that may be a bit more than other quotes you received, however the difference is in the higher quality material we use, the trained technicians that know the importance of preparation, and a longer lasting floor that you won't have to redo in your lifetime.

How do you prep the concrete?

Prior to installing an epoxy coating we thoroughly prepare the concrete. This involves diamond grinding, repairing cracks or imperfections, and filling joints as needed. Diamond grinding is necessary to a strong bond to the surface of the concrete. Grinding removes dirt, stains, and existing coatings while creating a scratch pattern for the epoxy to "bite" into.

How long is the process?

The timeline depends on the size and complexity of the project. On average, most 2 car garages can be completed in a single day with our standard system. An additional topcoat or primer can add an extra day each.

How long do I need to stay off the floor for?

Typically, you can walk on the surface 24 hours after the final coat is applied. Full cure times may vary based on weather conditions, but are generally achieved within 72 hours which is when it is safe to return to normal use.

How much flake is put down?

We offer full flake floors which use about 50lbs of flake per every 500sqft. This provides consistency that allows us to achieve a desirable texture and aesthetic without sacrificing durability.

Will the coating yellow over time?

No! Our coatings will not yellow over time. Our polyaspartic top coat is UV resistant unlike some epoxy and polyurea top coats used.

UPLOAD A PICTURE OF YOUR SPACE TO VISUALIZE YOUR NEW FLOOR.

UPLOAD A PICTURE OF YOUR SPACE TO VISUALIZE YOUR NEW FLOOR.

BOOK YOUR APPOINTMENT TODAY

Choose the Golden standard and get a coating that you know will last a lifetime

BOOK YOUR APPOINTMENT TODAY

Choose the Golden standard and get a coating that you know will last a lifetime

Proud to Sponsor

Hours

Weekdays: 9am - 5pm

Saturday: 10am - 3pm